Hygienic, safe, flawless:

High demands for the highest quality

Hygiene and safety are essential wherever food and beverages are produced. In order to ensure that the end product is of outstanding quality, the sensitive manufacturing, filling and conveying processes must be kept absolutely clean and free of germs and foreign particles. Another key factor is the exact dosing of substances.

In the face of global competition, companies have had to meet increasingly stringent requirements in recent years in order to comply with international standards and to meet the high demands of enlightened, critical consumers with an increasing demand for innovative, high-quality products.

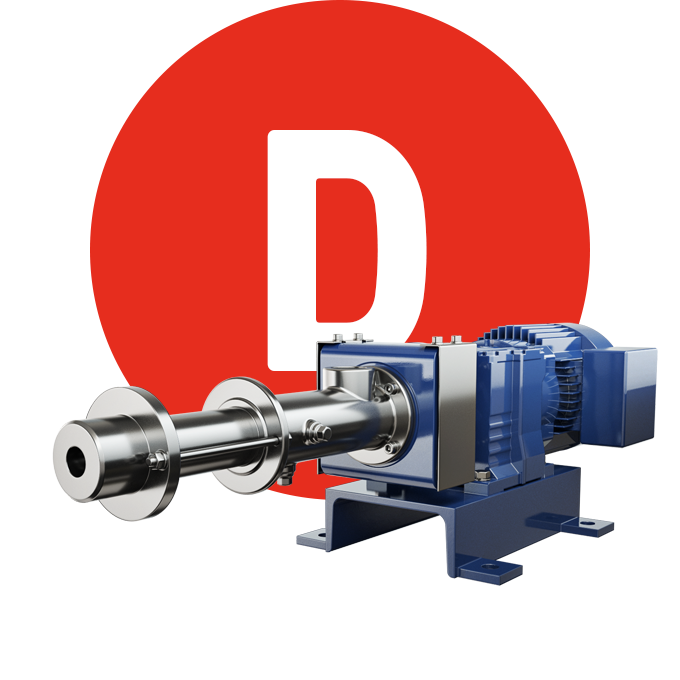

SEEPEX sets new standards

In few other sectors are the demands on pump technology higher than in the food and beverage industry. Hygienic cleanliness in all processes is an absolute must to ensure that products are safe to eat. Furthermore, high operational safety and reliability as well as easy, residue-free cleaning and fast maintenance also play a central role.

SEEPEX meets all requirements by providing pumps that comply with the strictest hygiene regulations and which also combine the gentle product conveyance of a progressive cavity pump with the ease of maintenance and reliability for which SEEPEX is renowned. Many product ranges are certified according to the US 3A-Sanitary Standards or the European guidelines regarding hygienic design (EHEDG). SEEPEX customers can therefore be sure of producing hygienically and microbiologically flawless food with these food pumps.